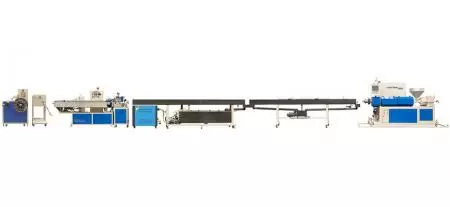

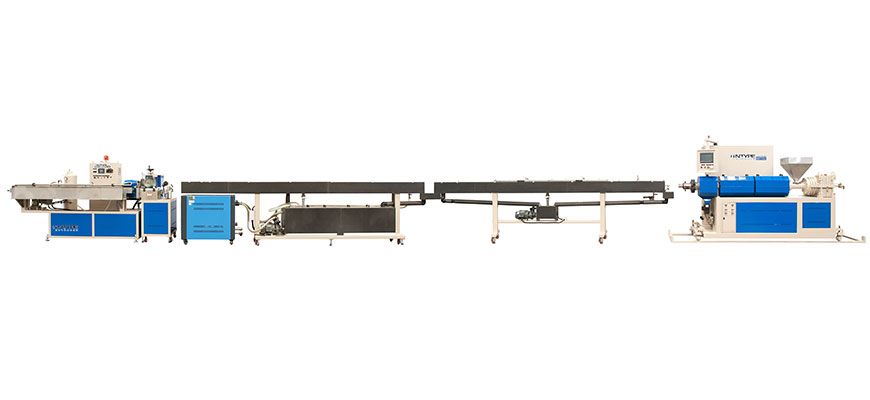

Medical Tube Extrusion Line

SEP

Intype's Medical Tube Extrusion Line is a cutting-edge solution designed for medical-grade plastic tubing production. With its superior performance, stability, and high output, the SEP Series ensures consistent wall thickness, precise dimensions, and exceptional quality, meeting the stringent demands of the medical industry. Trusted by top global medical equipment manufacturers, it has become the go-to choice for medical tube production equipment.

Materials and Customization

The Medical Tube Extrusion Line supports versatile material options, including PP, PE, PVC, and TPU, making it suitable for a wide range of medical tubing applications. Customers can customize the extrusion line to produce tubing with features such as transparent, matte, or smooth textures, single or multi-color designs, multi-lumen structures, co-extruded layers, and specialized applications like respiratory tubing or catheters.

Characteristic of the Machine

- 1. High Efficiency and Energy Savings:

- - Designed for high output and low energy consumption, the SEP Series utilizes SACM645 Japanese steel screws and barrels, delivering excellent plasticizing and mixing performance.

- - Long-lasting and efficient components ensure reliable operation and high-quality production.

- 2. Advanced Automation:

- - Integrated PLC control system enables full automation, with optional online quality inspection systems to minimize manual oversight.

- - Production data can be recorded, stored, and retrieved easily via USB for analysis and consistency, even when operators change.

- 3. Flexible Configurations:

- - Supports single-layer, multi-layer, or multi-lumen tubing production.

- - Capable of producing medical tubing in various colors, including dual-color and striped designs.

- 4. Wide Material Compatibility:

- - Perfect for manufacturing PVC medical tubes, TPU tubing, and PP/PE respiratory tubing, ensuring the adaptability of the extrusion line to customer requirements.

Optional Equipment

- Dosing System.

- High Speed Mixer & High Speed Cool Churning M/C.

- Raw Material Conveying System.

- Feeding & Storage System.

- Sound-Absorbing Type Strong Crusher / Feeder / Jumbo Bag Storage Tank.

- Air Compressor.

- Chiller Cooling System.

- Raw Material Belt Type Conveyor.

- Pulverize Machine.

- Belling Machine – Socketing Type, Belling Type.

- Collection Table.

- Winder Unit.

- Ink Jet System.

- Punching Unit.

- Chamfer Unit.

- Welding Unit.

- Bending Unit.

- Tunnel Metal Detector.

- Processing Equipment.

Application

• Medical Catheters and IV Tubes: Offers precision and reliability for applications demanding uniform wall thickness and smooth surfaces.

• Respiratory and Multi-Lumen Tubes: Produces multi-lumen and co-extruded tubing designs for advanced medical needs.

• Custom Medical Tubing Solutions: Suitable for applications like urinary catheters, flexible medical hoses, and specialized plastic medical tubes.

Digital control of components and actual monitoring of production processes and quality, which also means that we are always close to the needs of customers.

Medical Tube Extrusion Line | Plastic Profile Extrusion Solutions | Intype

Located in Taiwan since 1963, Intype Enterprise Co., Ltd. is a high efficiency plastic extrusion machines manufacturer. Their main plastic extrusion machines include, Medical Tube Extrusion Line, sustainable plastic extrusions, continuous bead foam machines, supercritical reaction pelletizers, medical tube extrusion lines and profile extrusion machinery. Their offerings also encompass medical tube extrusion lines and profile extrusion systems. Intype is committed to innovation, quality, and environmental sustainability, focusing on efficient, eco-friendly technologies.

Discover Intype's advanced Plastic Extrusion Machines, a blend of innovation and 60 years of expertise. Specializing in TPE Wood-like Profiles, Continuous Bead Foam, and Supercritical Reaction Pelletizing, our machines are designed for efficiency and sustainability. Ideal for B2B buyers in the plastic extrusion industry, our products range from Medical Tube Extrusion Lines to Profile Extrusion and Recycling Solutions. Intype machines are synonymous with quality, precision, and eco-friendliness, ensuring optimal performance and environmental responsibility. Join the forefront of plastic extrusion technology with Intype's reliable and advanced solutions.

Intype has been providing customers with high efficiency plastic extrusion machines since 1963, with both advanced technology and 50 years of experience, Intype ensures that each customer's requirements are met.