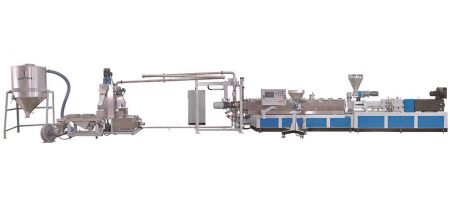

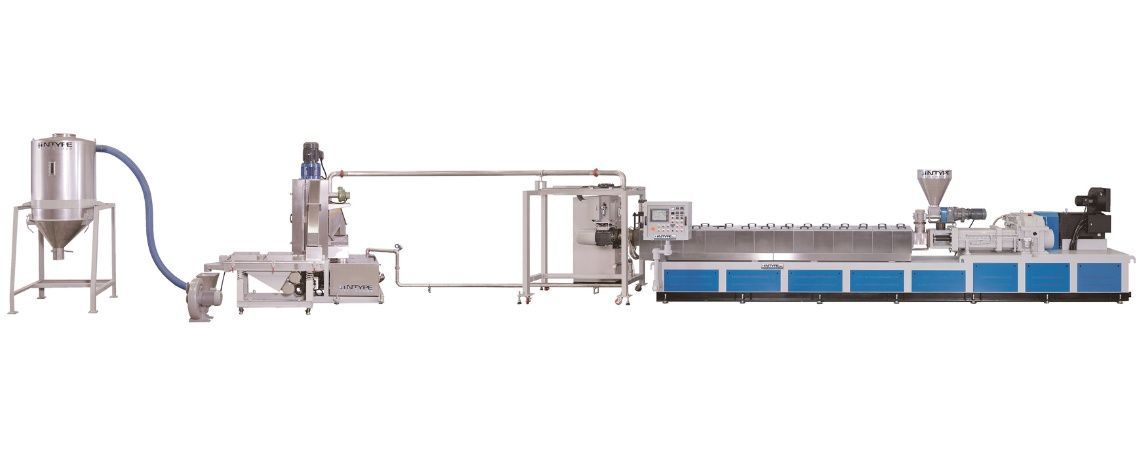

Under-Water Type Pelletizing Machine

TUP / REG / CEG

Suitable for many kinds of plastic and filler / additive compounding & pelletizing, especially suitable for material with high melting viscosity, which not easy to be pelletized by strand type system. During pelletizing processing, the final pellet is round and uniform size by centrifugal force. Based on client's material / additive and capacity requirement, extruder could be single screw extruder / twin screw extruder / co-rotating type twin screw extruder … etc.

Resin : TPR, PLA, HDPE, LDPE, TPE… etc.

Characteristic of the Machine

- 1. Machine is manufactured through a special screw design, can be applied to many types of plastic pelletizing.

- 2. Whole- plant design, process arrangement, manufacturing, installation and technical transfer turning customer's innovative ideas into profitable products.

- 3. Low-temp mixing designed screw is effectively lower energy consumption, and also maintain the raw materials character.

- 4. Vacuum assisted degassing system that helps efficiently to get rid of moisture, waste gas, and dust. The pellet out feed is more steady, and pellet is also stronger in density.

- 5. Straight transmission design collocates high torque output of heavy duty gear box, forced lubrication system ensures operation stability, low noise and guarantees high-quality, greater output under high speed operating.

- 6. Outstanding control system can collocate PLC computer to make control program, carry on full-auto/ semi- auto operation.

- 7. Customized designing requirement is welcome.

Specification

| SEG-085 | SEG-100 | SEG-120 | |

|---|---|---|---|

| Screw Dia. | Ø 85mm | Ø 100mm | Ø 120mm |

| L/D | 28 ~ 34 | ||

| Capacity | 200 ~ 250 kg/hr. | 300 ~ 400 kg/hr. | 500 ~ 600 kg/hr. |

* Customized designing requirement is welcome.

* Based on client's material / additive and capacity requirement, we have twin screw extruder to meet with client's demand.

* Machine model: CEG / REG.

Optional Equipment

- Pulverize Machine.

- High Speed Mixer & High Speed Cool Churning M/C.

- Feeding & Storage System.

- Raw Material Conveying System.

- Dosing System.

- Air Compressor.

- Chiller Cooling System.

- Storage System.

- Vent System.

- Vibration Unit.

- Bagging & Packaging & Weighing System.

- Material Convey System.

Application

Biodegradable Material Compounding / Coloring / Foam TPE Compounding / MasterBatch / Micro Pellet Compounding / Starch. PLA Compounding / Virgin Material Compounding.

Digital control of components and actual monitoring of production processes and quality, which also means that we are always close to the needs of customers.

Under-Water Type Pelletizing Machine | Plastic Profile Extrusion Solutions | Intype

Located in Taiwan since 1963, Intype Enterprise Co., Ltd. is a high efficiency plastic extrusion machines manufacturer. Their main plastic extrusion machines include, Under-Water Type Pelletizing Machine, sustainable plastic extrusions, continuous bead foam machines, supercritical reaction pelletizers, medical tube extrusion lines and profile extrusion machinery. Their offerings also encompass medical tube extrusion lines and profile extrusion systems. Intype is committed to innovation, quality, and environmental sustainability, focusing on efficient, eco-friendly technologies.

Discover Intype's advanced Plastic Extrusion Machines, a blend of innovation and 60 years of expertise. Specializing in TPE Wood-like Profiles, Continuous Bead Foam, and Supercritical Reaction Pelletizing, our machines are designed for efficiency and sustainability. Ideal for B2B buyers in the plastic extrusion industry, our products range from Medical Tube Extrusion Lines to Profile Extrusion and Recycling Solutions. Intype machines are synonymous with quality, precision, and eco-friendliness, ensuring optimal performance and environmental responsibility. Join the forefront of plastic extrusion technology with Intype's reliable and advanced solutions.

Intype has been providing customers with high efficiency plastic extrusion machines since 1963, with both advanced technology and 50 years of experience, Intype ensures that each customer's requirements are met.